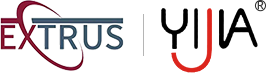

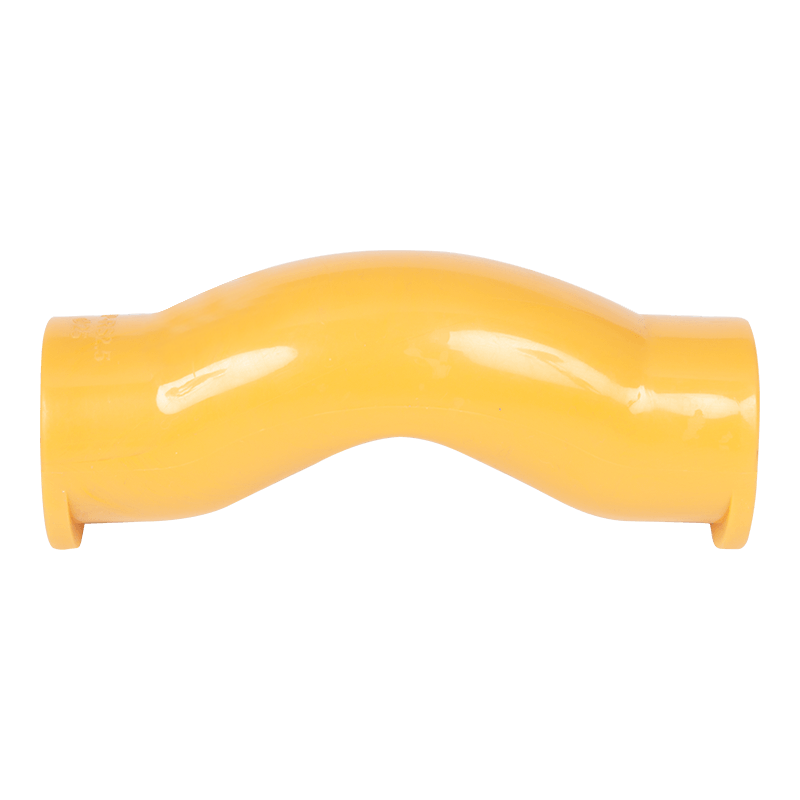

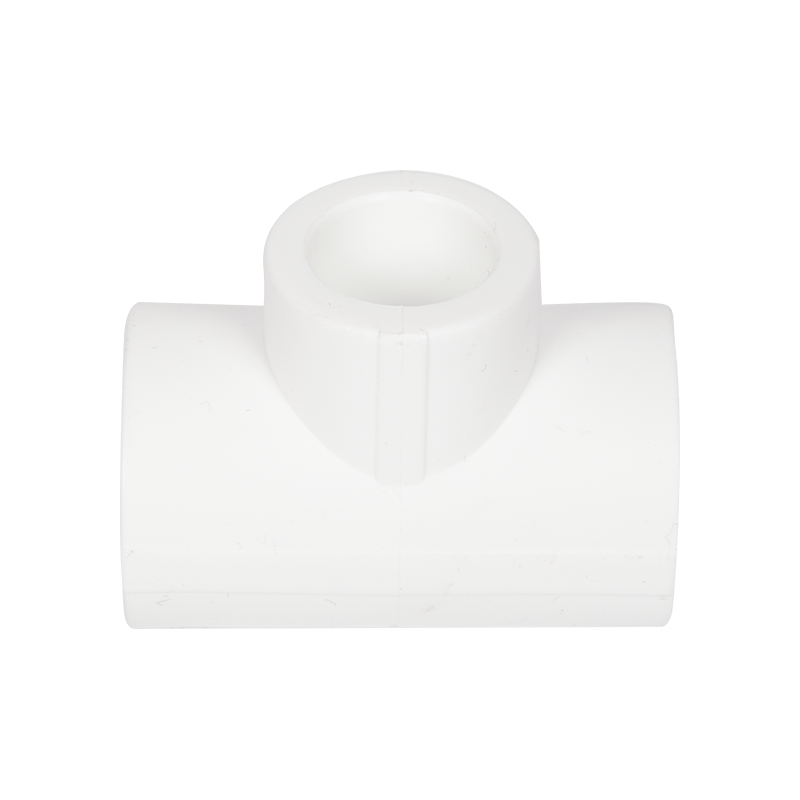

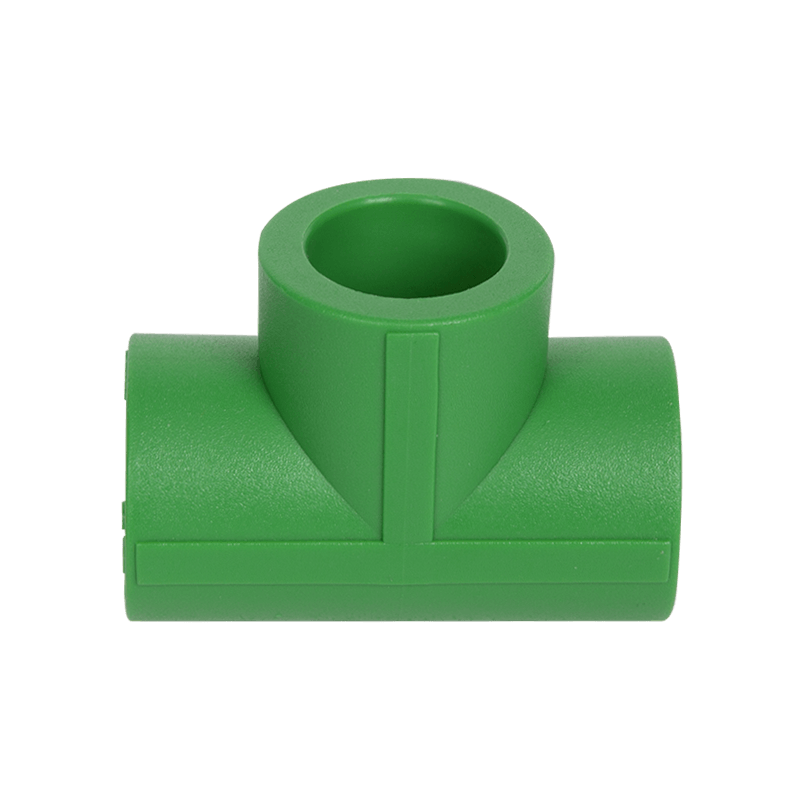

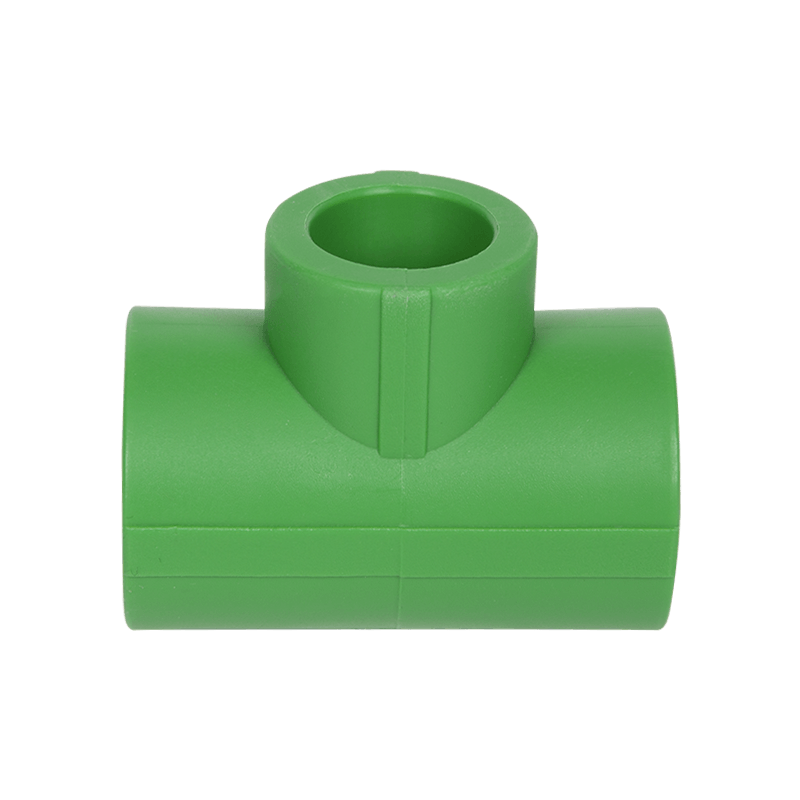

Plastic fittings are commonly used in various industries and applications due to their versatility, affordability, and ease of use. These fittings are typically made from thermoplastics such as PVC, CPVC, PP, and PE, and come in a wide range of shapes, sizes, and configurations.

Features and benefits:

Durability: Plastic fittings are known for their durability and resistance to corrosion, chemicals, and UV radiation. They are also able to withstand high temperatures and pressures, making them suitable for a variety of applications.

Affordability: Compared to metal fittings, plastic fittings are generally more affordable, which makes them a popular choice for a wide range of applications.

Ease of installation: Plastic fittings are easy to install and require minimal tools and equipment. They can be easily joined using various methods such as solvent welding, mechanical coupling, or compression fitting.

Versatility: Plastic fittings come in a wide range of shapes and sizes, and can be used for a variety of applications, including plumbing, irrigation, water treatment, chemical processing, and more.

Lightweight: Plastic fittings are typically lightweight, which makes them easy to handle and transport. This can be particularly advantageous in applications where weight is a factor, such as in the aerospace or automotive industries.

Chemical resistance: Plastic fittings are resistant to many chemicals, making them suitable for use in a variety of chemical processing applications.

Hygienic: Plastic fittings are non-toxic and can be easily sterilized, making them suitable for use in applications that require high levels of cleanliness, such as in the food and beverage industry.

Application:

Plastic fittings are available in a wide range of shapes and sizes, making them suitable for use in a variety of applications. They can be manufactured using different types of plastics, including polyvinyl chloride (PVC), polyethylene (PE), and polypropylene (PP). Each type of plastic has its unique properties and benefits, making it important to select the appropriate type of fitting for a particular application.

In the plumbing industry, plastic fittings are widely used for both residential and commercial applications. PVC fittings, for example, are commonly used in drain, waste, and vent systems, as well as in irrigation and pool systems. PE fittings are often used in water supply lines and gas distribution systems, while PP fittings are commonly used in chemical processing and water treatment systems.

In the HVAC industry, plastic fittings are used for air conditioning and ventilation systems. PVC and PE fittings are commonly used in ductwork and air distribution systems, while PP fittings are often used in chemical fume hoods and laboratory exhaust systems.

In the automotive industry, plastic fittings are used for a wide range of applications, including fuel systems, air intake systems, and coolant systems. Plastic fittings are ideal for these applications because they are lightweight, durable, and resistant to chemicals and solvents.

In conclusion, plastic fittings are a versatile, affordable, and durable option for a wide range of applications. They are easy to install, lightweight, and resistant to corrosion, chemicals, and UV radiation. With its many benefits, plastic fittings are a popular choice in industries such as plumbing, irrigation, chemical processing, and more.

JAZYK

JAZYK